ABOUT US

UGDBF (University of Glasgow Design Build Fly) is a group of students at Glasgow University competing to take part in the annual AIAA DBF competition. Every year since 2015 we have risen to this challenge, with 3 of these as the sole UK competitive team.

UGDBF brings together students of all faculties, age, experience and disciplines to develop a competitive and world-leading aircraft design in an ever expanding and developing workplace environment tailored to encourage innovation and professional development.

UGDBF boasts a strong ethos of engagement and accessibility meaning all of our members experience a hands-on learning environment from day 1 until the end of their career.

We are currently building our 2019 aircraft to be flown in Tuscon, AZ and are looking to recruit for Wichita 2020. Will you come fly with us?

2020 - Kansas

UDBF returns with a new innovation for 2020 in Kansas. Watch this space for the announcement of the UGDBF-200 aircraft after report week!

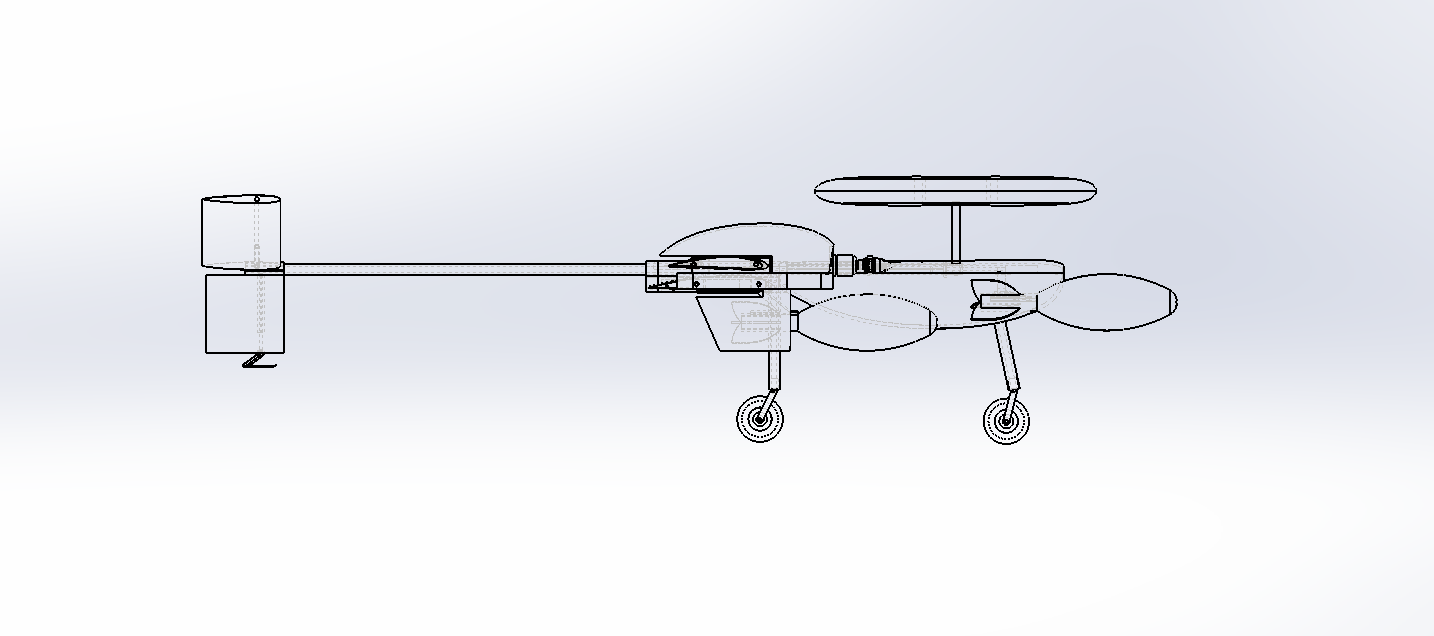

2019 - Arizona

2019 proved a challenging year for UGDBF. The UGDBF-194 made a number of breakthroughs in aircraft design as well as size with a wingspan of 3.2m it is by far the largest aircraft realised by UGDBF. A rear mounted pusher boost prop mounted aft of the tail, leading edge impact attenuators, an onboard control computer for its' systems as well as differential thrust for improved mobility made Maddie the most involved aircraft to design, manufacture and operate. Combined with a number of logistical issues, a 66th place finish from 104 teams put the perserverance of UGDBF to the test once more but the lessons learnt were invaluable for paving the way for the next step in UGDBF aircraft.

2018 - Kansas

Following on from the success of the 2017 year, the short-span, heavy lift aircraft Bertha was the first aircraft to heavily feature the use of CFD for wing design. In order to extract the maximum amount of lift per unit span, numerous flow control devices were added to the design to calm errratic behaviour in non-steady flow conditions. A key feature of this delta wing configuration was its' oversized winglets designed to improve lift near the ground as well as provide lateral area near the rear of the aircraft to compensate for the reduced yaw authority of the V-tail. Extremely incelement weather resulted in extremelly difficult flying conditions in 2018, and despite the robustness of the design impacted score.

2017 - Arizona

2017 would prove to be challenging but extremely rewarding and successful year for the team. After a dissapointing previous result the previous yuear and sub-optimal flying conditions during the first competition year in Kansas, UGDBF returns to form with a fully revised technical programme. Gigi incoporated a number of advances made internally - extending the use of CNC manufacturing for critical wing components and fully leveraging the data gathered in previous years. Deployable from her tube in under 30 seconds, UGDBF arrives to the competition with a skeleton crew of 2. Despite reduced personnel, the dynamic duo took topthe skies enough to fill over 2 complete fligt sheets under critical acclaim for a final result of 21st.

2016 - Kansas

2016 would prove to be one of the most challenging years for UGDBF. Kicking off the year with the in-house assembly of a foam CNC cutter, the 2016 comeptition year proved to be a significant technical challenge. Aiming to use morer conventional construction methods and a focus on increased prototyping, this year marked the first where mass production of modular components began. With a focus on the core design, the production aircraft designated Bee was found to be an excellent conventional aircraft and continues as a show plane to this day. Placing UGDBF 21st in the final ranking.

2015 - Arizona

The inaugural year for UGDBF. After much trial and error, the first prototype aircraft to leave the workshop, dubbed Chantelle takes to the skies above Scotland early in 2015. Made from entirely new processes, the CF-Foam sandwhich and carbon-resin infusion subframe are designed to withstand over maneuvrers of over 5G with a unified servo setup. With 3 servos on board for the elevator, ailerons and nose gear, and payload control 2015 marks the debut for UGDBF. With a report score of 92.5 and a RAC placing the team solidly in the midfield, UGDBF achieves a 19th place finish. From this moment onwards, UGDBF cements itself as a solid contender for future DBF competitions with a unique take on aircraft design.